Our business is built on partnering with our clients so you know exactly what you are getting. Partnering with your molder in the early stage of product development gives you the opportunity to make design improvements and fix problems in advance—saving you time and money. Whether your mold is built by us or one of our top-tier molders off-shore, we make sure the mold meets our standards of quality and reliability.

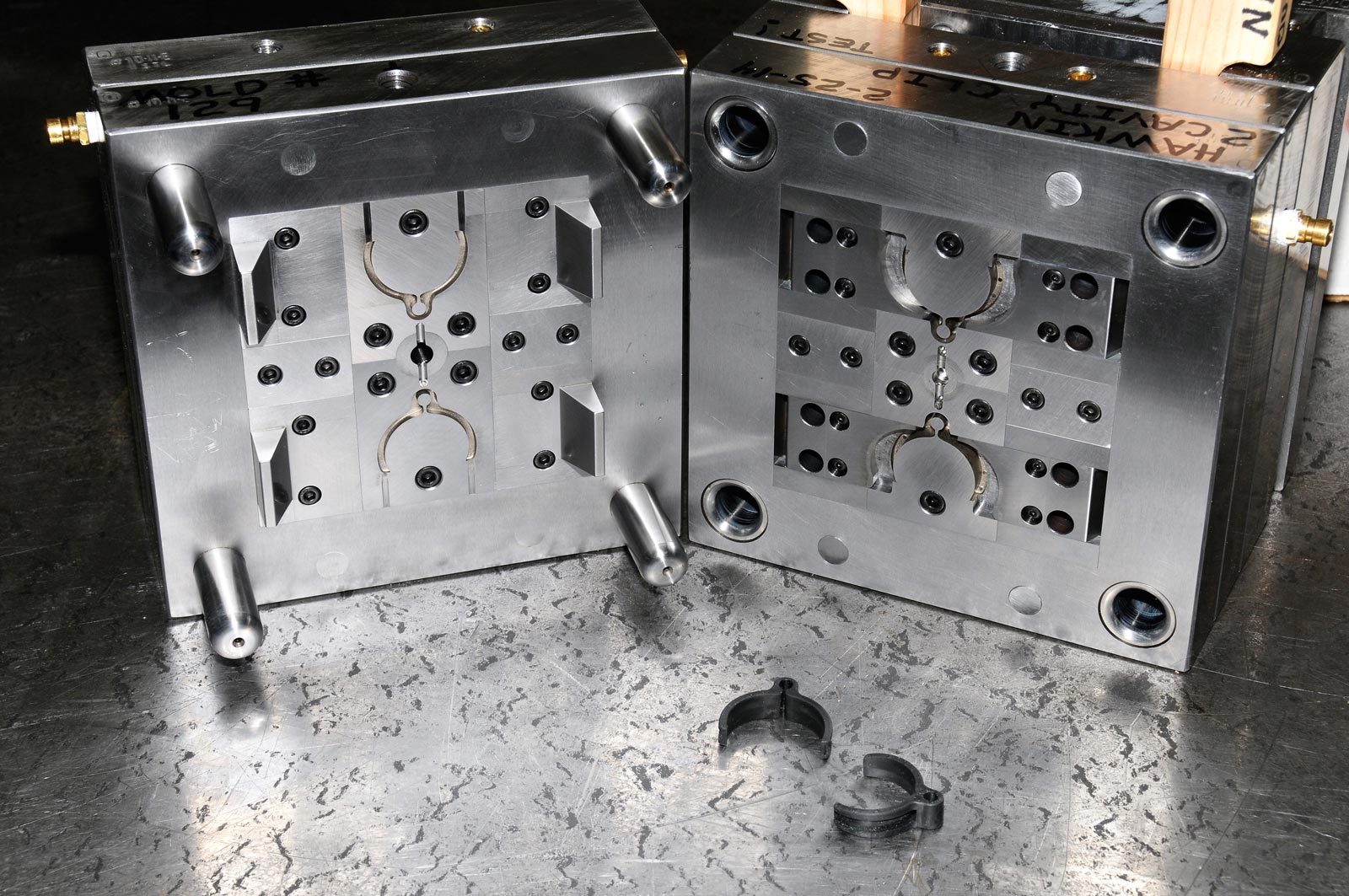

From prototype to finished product and final delivery, our DFM (Design for Manufacturing) engineering team works with you every step of the way. Design reviews make sure we are on the same page—from start to finish. We take pride in staying true to our roots by our relentless commitment to quality and being the best at what we do. We specialize in intricate mold designs and high-volume manufacturing. If you need complex parts, we are the molder for you.

Materials

- Aluminum

- Soft Steel (P20)

- Hard Steel (H13, S7, 420SS)

Types of Molds

- Prototype

- Production

Secondary Operations*

- Ultrasonic Welding

- Assembly

- Printing, etc.

*We also have a list of expert partners for any service we can’t do in house; whether it’s automation for your specific insert molding needs or A1 diamond polishing—we’ll be sure it’s done right

Tooling

At Messenger Molding, we make high quality molds to industry standards! Put us to the test. Many top Biomedical Corporations domestic and abroad are satisfied customers and have increased profitability as result of working with Messenger Molding.

For example, one company required a guarantee of a 3 million shot life span and their mold is now over 10 million with little or no maintenance.

Injection Molding

While we have always built the highest quality molds in-house, we understand in this increasingly global economy, many of our customers desire off-shore solutions. We have established relationships with top-tier molders in Taiwan and China.

Secondary Operations

Let our experts provide the finishing touches: sonic welding, printing, assembly, drilling and tapping, and more.

Other Services

- Clean room molding

- Packaging—made to fit your product and your needs

- Shipping

- We ship anywhere in the world and will meet your shipping specifications. Whether your project requires contaminant free or anti-static packaging, heat sealing, humidity or temp control, we can provide it.

- We have shipped with all carriers and can work with your preferred method

- We also provide JIT delivery services for some of our customers