DECADES OF EXPERIENCE

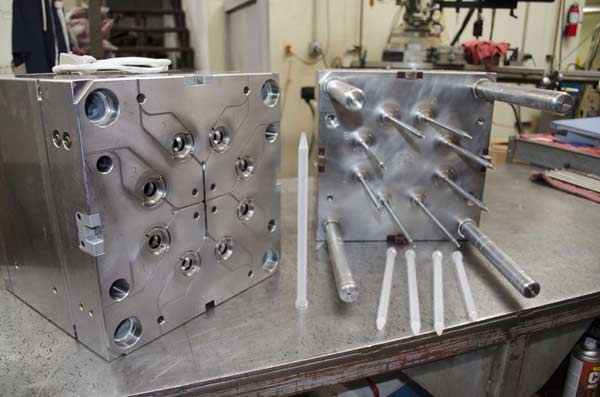

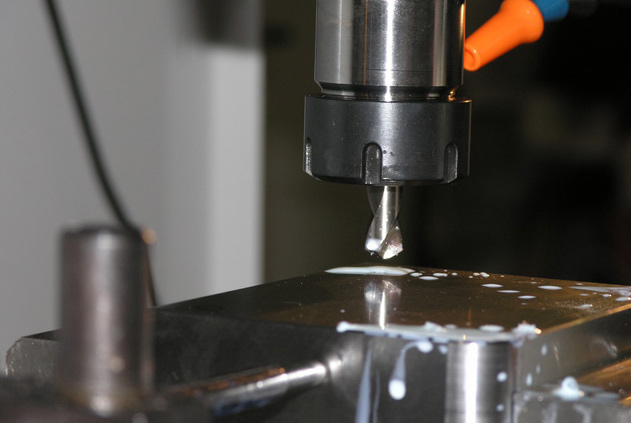

For nearly 40 years and two generations, Messenger has been providing custom designed, high-quality, precision tooling and plastic injection molding to clients all over the world. Our proven track record and list of customers show we are committed to providing you the best quality in the industry.

Messenger specializes in high-tech, tight tolerance, precision mold design. As a full-service molder, we take pride in building relationships with our customers so your product is designed and built exactly to your specifications. Our team works with you one-on-one to be sure you are satisfied.

Whether you have a simple design or very complex requirements, our engineering team and experienced craftsman will take you from initial concept through final production and packaging.

We work with you from start to finish!